Topics

Safety signs test methods (Update)

2023-11-23

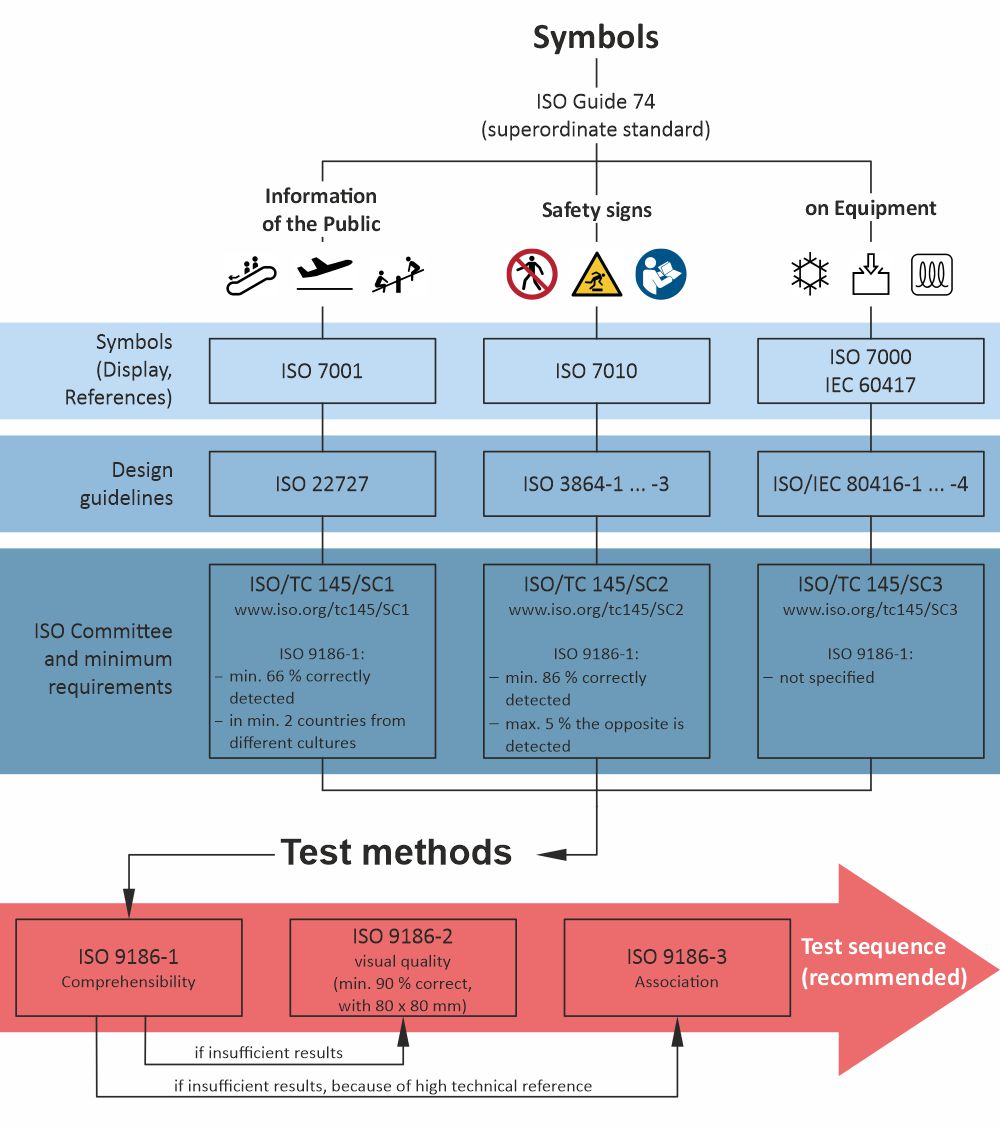

ISO 7010 provides some safety signs. However, depending on the application, these are often either too general, too specific or not available for the specific case. In order to warn the user as precisely as possible, safety signs must therefore be created on the basis of ISO 3864. ISO 9186 provides a clear indication of whether these safety signs are recognized with sufficient accuracy, with test methods for comprehensibility, visual quality and association with the subject of the symbol.

The ISO 9186 series of standards has also been developed and is actually applicable for all other applications in which information is to be represented by symbols. The three parts of ISO 9186 first address large parts to the standards bodies themselves by describing the procedures how symbols proposed for standardization are submitted to the committees of ISO or the National Standards Bodies. However, the part of the procedures dealing explicitly with symbol testing can be readily applied to an application in an industrial environment.

Ready-to-use test documents

- Comprehensibility tests of symbols and icons according to ISO 9186-1

- Test of the visual quality of symbols and icons according to ISO 9186-2

- Association tests of symbols and icons according to ISO 9186-3

Included are:

- Instructions for administrators (*.docx)

- Instructions for respondents (*.docx)

- Sample test pages (*.docx) and

- Evaluations (*.xlsx)

Test methods

The assessment of the recognizability of graphic symbols is a complex task. It is influenced by a wide variety of factors and conditions (ISO 3864-1 Annex A):

- Size of the individual symbol elements in relation to the geometric shape of the symbol;

- Illumination of the safety sign from the outside or transillumination and materials used;

- Contrast between symbol and background;

- Viewing angle;

- Visual acuity of the viewer;

- Familiarity with the object or shape depicted.

- Of course, before symbols can be tested, they must be created according to standardized design guidelines.

The following overview provides the normative basis for design and testing methods:

ISO 9186-1, important points …

“Graphical symbols – Test methods -.

Part 1: Method for testing comprehensibility”.

- Comparative tests of up to 3 symbol variants should always be conducted.

- Respondents should answer with knowledge of the context to the questions:

“What does this symbol mean?”

“What action is the symbol supposed to trigger?” - Presentation of symbols on paper or on screen in bw, in size 28 x 28 mm,

for safety symbols with basic symbol and explanation of basic symbols. - 50 respondents from the target group (familiar with the context) per symbol variant in each test country.

- A self-report of the respondents supports the evaluation of the results.

- The symbol that was recognized correctly the most often is the most understandable symbol.

- The standard does not specify a minimum number of correct answers, but the ISO (ISO/TC 145) specifies minimum requirements for symbols proposed for standardization (see scheme).

- If a symbol is not sufficiently understandable, additional text is recommended.

ISO 9186-2, important points …

“Graphical symbols – Test methods -.

Part 2: Method for testing perceptual quality”

- The test should be used when the comprehensibility test (ISO 9186-1) has shown difficulties in recognizing the symbol.

- Test of recognizability of the elements of a symbol under viewing conditions simulating reality but standardized:

Viewing distance 2 ± 0.04 m

View perpendicular 90 ± 10° to the presentation plane

illumination between 95 lux and 105 lux - Respondents are asked to describe all elements of the symbol without knowledge of the context, i.e. not to name the meaning of the symbol (naming task).

- 25 respondents per symbol size, with a maximum of 15 symbols in one size.

- At least two symbol sizes are tested, always 80 x 80 mm (min. recognition rate approx. 90%) and another, safety signs always also in the size 50 x 50 mm.

- A self-report of the respondents supports the evaluation of the results.

- Correctly recognized is, if a shape e.g. as “circle” or the object “wheel” was recognized correctly. A percentage of correct identifications is determined for each symbol size. The standard only indirectly mentions a minimum number for correct answers, and ISO (ISO/TC 145) also does not mention any minimum requirements (see scheme).

ISO 9186-3, important points …

“Graphical symbols – Test methods – Part 3:

Method for testing symbol referent association”

- Test whether symbol and meaning can be correctly associated if respondents have been familiarized with it before.

- Particularly suitable when symbols without additional text are to be tested for technical personnel.

- The comprehensibility test (ISO 9186-1) can, despite suitably selected respondents (target group), too often result in the answer “don’t know” for symbols with a high technical reference, because the respondents are unfamiliar with the meanings of the symbols despite their technical reference.

The symbol association test (ISO 9186-3) therefore introduces the respondents to the meanings of the symbols in a first step. - In the symbol association test, respondents are asked to associate a symbol with the correct meaning from a list.

- Min. 25 respondents who have successfully gone through familiarity training.

- Symbols in bw, except when color is necessary to convey information.

- A respondent self-report assists in scoring the results.

- The test provides a percentage of correct identifications. Neither the standard nor ISO (ISO/TC 145) specifies a minimum number for correct answers.

Conclusion

In principle, all parts of ISO 9186 remain open as to the results with which a symbol can be considered sufficiently comprehensible. ISO Technical Committee 145 does state minimum requirements (see Fig. 1), but seems to pay little attention to them, as can be seen from the “Additional information” for each safety symbol in ISO 7010:

- ISO 7010-W027 “Warning against optical radiation”.

“Test results according to ISO 9186-1 are only available from one country. These national test results indicate that the safety sign does not adequately meet all detectability criteria. …“ - ISO 7010-W028 “Warning of oxidizing substances”.

“Test results according to ISO 9186-1 are only available from one country. These national test results show that the safety sign sufficiently fulfills all detectability criteria. …“ - ISO 7010-M020 “Use restraint system”

“Test results according to ISO 9186-1 are not available. …“

Of the 108 safety signs in ISO 7010:2016-10, only 9 meet “all detectability criteria,” 17 meet “not all detectability criteria ” and no test results are available for 82. The status is no different in the amendments published between 2010 and 2015 (A1 … A5) with additional safety signs.

Blind application of standards is quite obviously relativized with this knowledge and clarifies that application of standards does not exempt from competence. Nevertheless, almost ironically, one is on a good path with the application of the safety signs from ISO 7010, because the broad use continuously increases the recognition rate through familiarity. Should comprehensibility tests be conducted with the safety signs 6 years after the publication of ISO 7010 in accordance with ISO 9186-1, acceptable recognition rates could be assumed.