Topics

Screenshots of machine controls

2020-04-14

After the technical illustrators had freed themselves from the chains of the design department and even took the 3D CAD data into their own hands, the dependency on the developers of the machine and system controls is unbroken. It can still be very time-consuming to produce screenshots of controls in defined states and in good quality. Despite objective limitations, “screenshots” can still be generated efficiently in alternative ways and can also be kept within standardized translation processes.

Typical operation

- real photos of user interfaces of the control

- classic screenshots in the development environment

- Export of the screens from the development environment as raster image

Photo of the user interface of a machine control system

Disadvantages of the typical mode of operation

- direct access to control and machine is necessary

- often only possible with the support of the developer

- Test stands or in simulation environments may be necessary

- for localized controls, all steps to create must be repeated

- hardly parallel working of development and documentation possible

Technical illustrators typically lack access to the development environment and the know-how to use it. But “screenshots” of machine or plant controls can actually only be created in the development environment. Mostly even only on test stands or in simulation environments. Similarly, direct access to the machine or plant can be difficult, for example due to long distances, plants that have already been commissioned and handed over to the customer or subsequent updates.

Alternative method

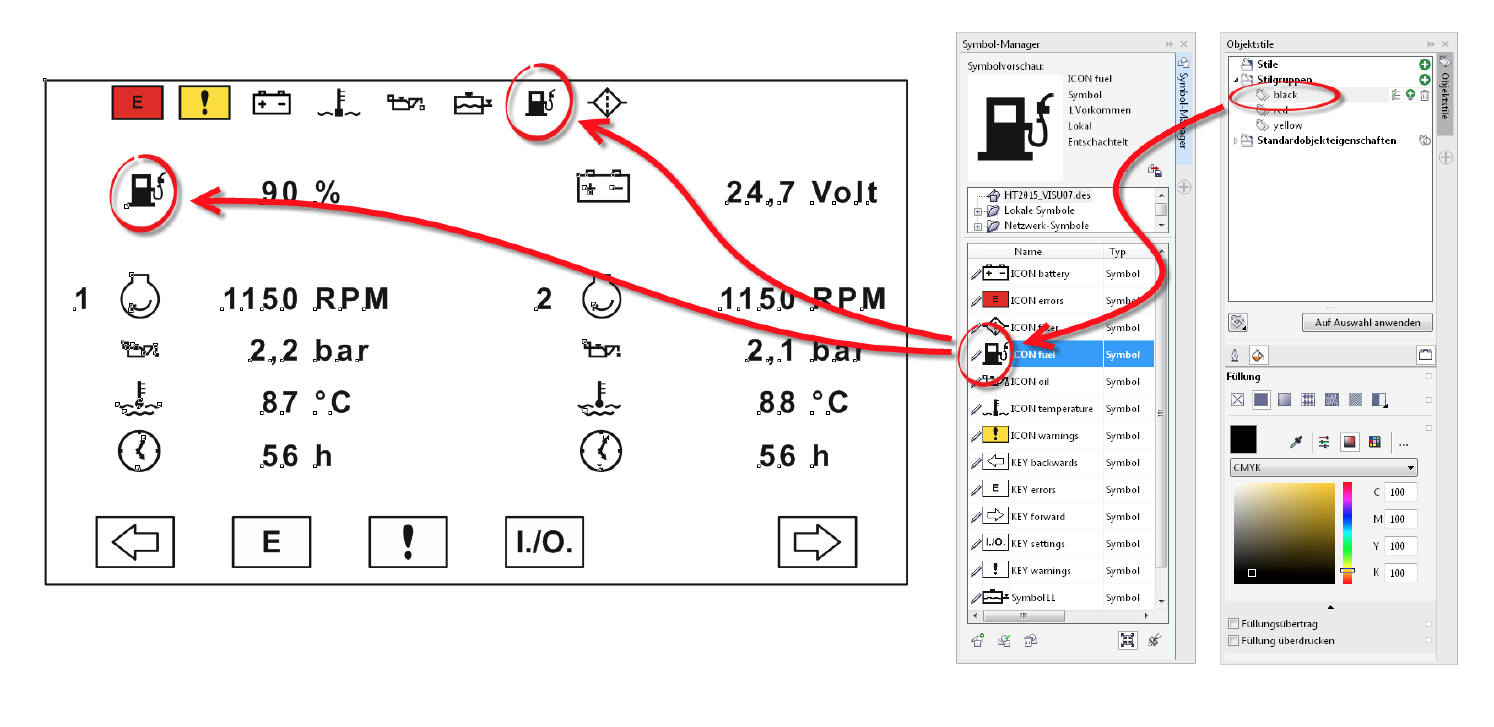

An efficient alternative for suitable projects has proven to be the implementation of the screens of the control software as structured vector graphics with specifically manipulable objects. The graphically comparatively simple interfaces of the control system are completely reproduced as vector illustration. Since it can be assumed that a control software and its user interface are subject to a possibly long life cycle, attention must be paid to optimal changeability when creating the “vector screenshots”.

In the Corel DESIGNER provide for optimal changeability:

- Object styles

- External and internal referenced symbols

- Groups

- Levels

Even if the functional use of Corel functions should be clear, nothing works without a small pragmatic graphic concept. In this graphic concept, on the basis of one or more real screenshots of the control, object styles with properties and semantic naming as well as a systematic for symbols, groups and layers must be defined.

User interface of a machine control system can be manipulated as vectors

Once editable data is available, Corel DESIGNER supports this by exporting and importing the texts to be translated in XLIFF format (XML Localization Interchange File Format), which ensures easy exchange with translation memory software.

Texts of a user interface in the translation process with XLIFF

Advantages of the alternative working method

- best graphic quality

- very easy adjustment of every possible situation of the machine, also every faulty situation

- no direct access to control and machine necessary

- no direct support of the developer necessary

- very good preparation and implementation of the localization

- localization no longer takes place in the development department, but in the documentation department with a corresponding influence on language and terminology, and only then does it find its way back into the control system

- parallel working of development and documentation becomes possible

- grown independence from the development department

- grown possibility of influencing the design of the user interface

Disadvantages of the alternative method

- graphic concept must be created once

- graphic template must be created once

- screenshots have to be recreated practically manually

Conclusion

As vector objects replicated screens of control systems, technical writers can free themselves from supposedly irrefutable processes of mechanical and plant engineering documentation and ensure new creativity and efficiency.